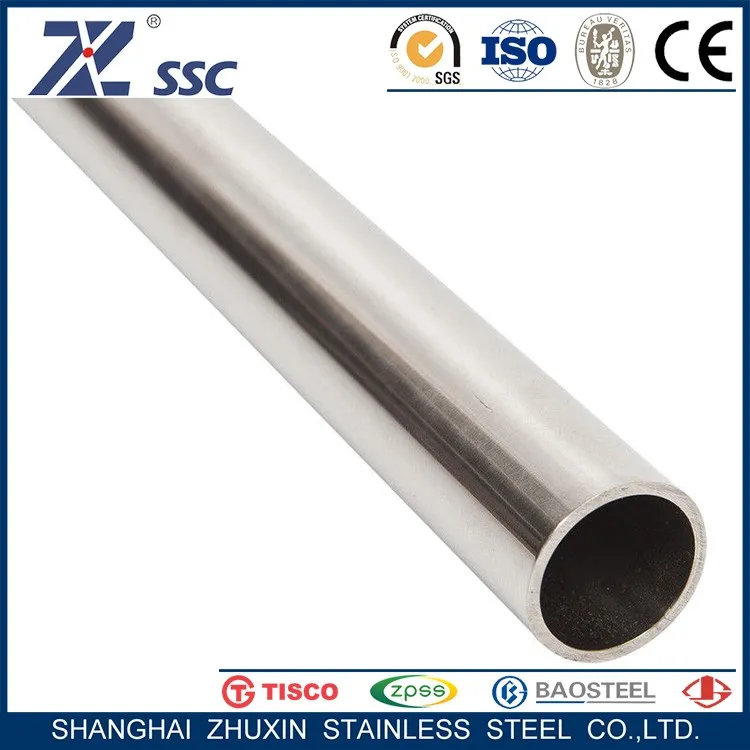

Brand Name: Zhuxin

Model Number: 201/304/304L/316/316L/430

Place of Origin: Shanghai, China (Mainland)

Standard: ASTM, AISI, DIN, EN, GB, JIS

Type: Welded

Steel Grade: 200/300/400 Series

Application: Food Industry,Construction

Certification: SGS,BV,ISO

Welding Line Type: EFW,ERW

Thickness: 1mm-40mm

Outer Diameter: 6mm-660mm

Surface: Mirror/Satin/Hairline/Polish

Length: 2mm-12mm, or Customized

OEM: Accept

Sample: Free

Trading terms: FOB CIF CFR CNF EXWORK

Technique Standard: Food Grade

Zhuxin Stainless Steel

Specifications:

| Commodity | Food Grade Sanitary Welded Stainless Steel Tube |

| Standard | ASTM/AISI/GB/DIN/JIS/EN |

| Material Grade | 201/202/304/304L/316/316L/430 |

| Certification | SGS,BV,ISO |

| Outer Diameter | 6mm - 660mm |

| Wall Thickness | 1mm - 40mm |

| Length | 2-12m, or customized |

| Tolerance | a) Outer Diameter: +/-0.2mm |

| b) Thickness: +/- 10%, or customized | |

| c) Length: +/- 10mm | |

| Surface Finish | Satin/Hairline: 180#/ 320# |

| Polish: 400#/ 600#/ 800#/ Mirror | |

| Process Method | Cold Drawn/EFW/ERW |

| MOQ | 0.5 Ton |

| Productivity | 3000 Tons/Month |

| Packing | Standard export package, or as requested |

| Delivery | 5-15 days after receiving the deposit |

Technical Requirement:

| TYPE NO. | C | Mn | P | S | Si | Cr | Ni |

| % | % | % | % | % | % | % | |

| 201 | ≤0.15 | 5.5-7.5 | ≤0.050 | ≤0.03 | ≤1.00 | 16.0-18.0 | 3.5-5.5 |

| 202 | ≤0.15 | 7.5-10 | ≤0.060 | ≤0.03 | ≤1.00 | 17.0-19.0 | 4.0-6.0 |

| 301 | ≤0.15 | ≤2 | ≤0.045 | ≤0.03 | ≤1.00 | 16.5-18.0 | 6.0-8.0 |

| 302 | ≤0.15 | ≤2 | ≤0.045 | ≤0.03 | ≤1.00 | 17.0-19.0 | 8.0-10.0 |

| 304 | ≤0.08 | ≤2 | ≤0.045 | ≤0.03 | ≤1.00 | 18.0-20.0 | 8.0-10.5 |

| 304L | ≤0.03 | ≤2 | ≤0.045 | ≤0.03 | ≤1.00 | 18.0-20.0 | 8.0-12.0 |

| 316 | ≤0.08 | ≤2 | ≤0.045 | ≤0.03 | ≤1.00 | 16.0-18.0 | 10.0-14.0 |

| 316L | ≤0.03 | ≤2 | ≤0.045 | ≤0.03 | ≤1.00 | 16.0-18.0 | 10.0-14.0 |

| 321 | ≤0.08 | ≤2 | ≤0.045 | ≤0.03 | ≤1.00 | 17.0-19.0 | 9.0-12.0 |

| 410 | ≤0.15 | ≤1.00 | ≤0.040 | ≤0.03 | ≤1.00 | 11.5-13.5 | |

| 430 | ≤0.12 | ≤1.00 | ≤0.040 | ≤0.03 | ≤1.00 | 16.0-18.0 |

Mechanical Properties:

| TYPE NO. | Y.S | T.S | ELOG. | Hardness | ||

| N/mm2 | N/mm2 | % | HB | HRB | HV | |

| 301 | ≥205 | ≥520 | ≥40 | ≤207 | ≤95 | ≤218 |

| 304 | ≥205 | ≥520 | ≥40 | ≤187 | ≤90 | ≤200 |

| 304L | ≥175 | ≥480 | ≥40 | ≤187 | ≤90 | ≤200 |

| 316 | ≥205 | ≥520 | ≥40 | ≤187 | ≤90 | ≤200 |

| 316L | ≥175 | ≥480 | ≥40 | ≤187 | ≤90 | ≤200 |

| 321 | ≥205 | ≥520 | ≥40 | ≤187 | ≤90 | ≤200 |

| 410 | ≥205 | ≥440 | ≥20 | ≤201 | ≤93 | ≤210 |

| 430 | ≥205 | ≥450 | ≥22 | ≤183 | ≤88 | ≤200 |

Competitive Advantage:

(1) Heat and corrosion resistance

(2) Fine mechanical properties

(3) Great intensity in low temperature

(4) No hardening phenomenon when in heat treatment

(5) Good hot workability such as in stamping and bending

(6) Non-magnetic

Applications:

(1)Construction

(2)Decoration

(3)Engineering

(4)Machine

(5)Industrial material

(6)Chemical industry

(7)Food industry

(8)Boiler heat exchangers

(9)Natural gas industry

(10)Pharmaceutics

(11)Water transfer

(12)Environmental protection

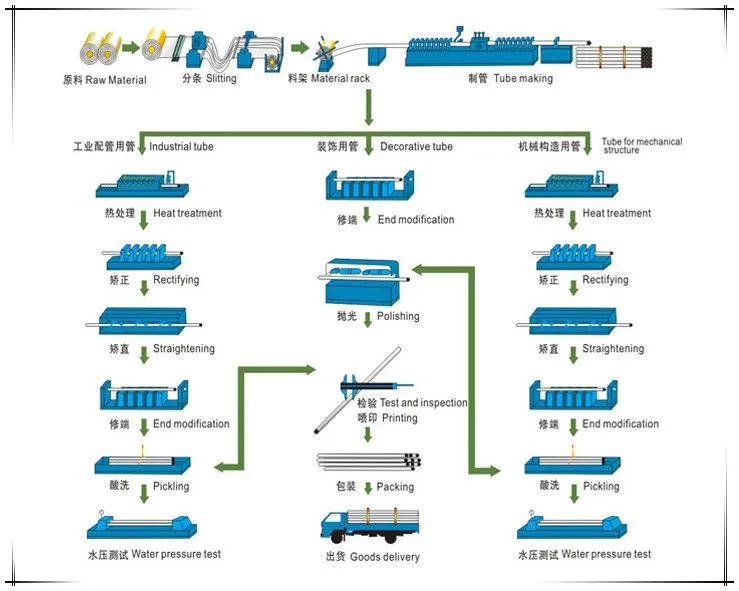

Process Flows: